This page covers the below sections:

- What is Mica and what are the concerns about its use?

- Why is Mica used in cosmetics?

- What are the Alternatives?

- What is the industry doing?

- What can the consumer do?

- Resources

- How can I use Responsibly Sourced Mica?

- What is the industry doing?

- References

See the Contents for all available Sustainability Hub pages.

What is Mica and what are the concerns about its use?

Mica is the name given to a series of silicate minerals that are found all over the world, currently mica is mined in more than 35 countries. The term mica covers 37 different phyllosilicate minerals, that occur in a layered structure(1).

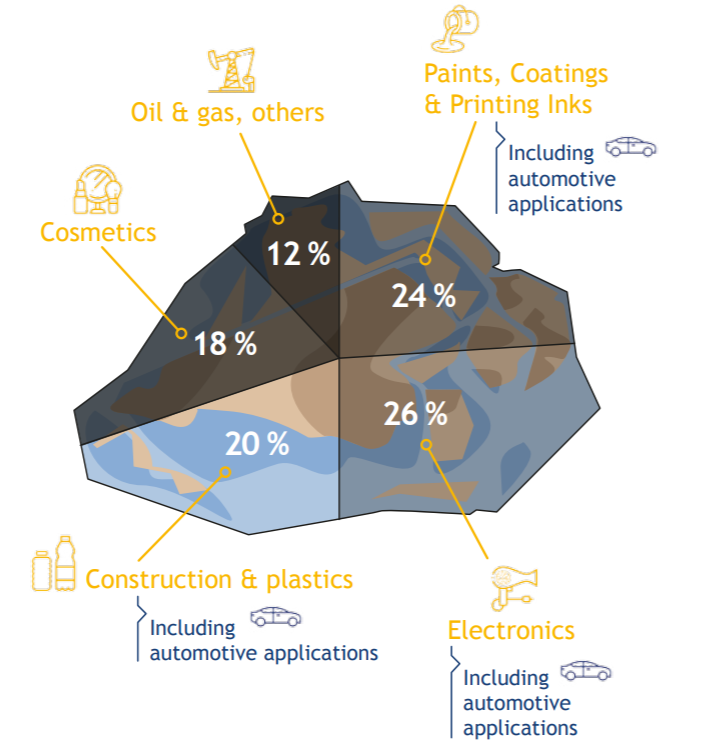

Mica is used in many industries. The electronics industry is the biggest user, using about 26 percent of the world’s mined mica. It is used in semiconductors, circuit boards and lithium ion batteries. When ground it can be used in electrical cables and for insulation(1).

This is followed closely by the paints, pigments, and ink sector (about 24%). Here, it acts as an anti-friction, anti-fouling, anti-settling, anti-corrosive, and anti-seizing agent. Overlapping layers of mica improve the integrity and durability of paint. Paints containing mica are used on a wide range of vehicles, including cars, lorries, and aircraft. In the automotive industry, apart from being used in paint, it is also added to the plastic used for bumpers and other castings as a filler(1).

About 18% of the mined mica is used in the cosmetic and care industry(1). Mica is used in many decorative cosmetic products, such as eyeshadows and lipsticks, to provide lustre or sparkle. Due to the platelet structure it can also be used in skin care products to help disguise fine lines and wrinkles. In body lotions it can give a soft sheen to the skin and it has been used widely, in recent years, in toiletries where is provides enhanced on-shelf effects when products are in transparent packaging.

About 18% of the mined mica is used in the cosmetic and care industry(1). Mica is used in many decorative cosmetic products, such as eyeshadows and lipsticks, to provide lustre or sparkle. Due to the platelet structure it can also be used in skin care products to help disguise fine lines and wrinkles. In body lotions it can give a soft sheen to the skin and it has been used widely, in recent years, in toiletries where is provides enhanced on-shelf effects when products are in transparent packaging.

Source: Responsible Mica Initiative 2019 annual report

India and China are the main producers of natural mica, between them exporting 325 kilotons in 2019(1). Within India, mica is sourced from a number of states in the North and East of the country, with Bihar and Jharkhand accounting for the major share of Indian mica(1). The states where mica is found are amongst the poorest in India. The part of Jharkhand where the mica is found is very remote and cut off from other regions. The land is poor and difficult for irrigation meaning that agriculture is not a viable means for self-sufficiency(1). As a result, the region is prone to labour abuses and the use of child labour. For many the mica that their children collect is the sole income for their families(2).

Child labour involved in the mining of mica has also been identified in Madagascar(2).

The cosmetics industry is committed to sourcing mica sustainably. Developing nations are confronted with many difficulties and individual companies have codes of conduct in place that consider the communities with which they work. Cosmetic manufacturers also work with their suppliers to create local sustainable sources wherever possible. This helps to avoid practices where people of all ages could be exploited and seeks to introduce labour standards which preclude the employment of children.

Companies often work with organisations, such as NGOs and charities, on specific initiatives in the countries affected in order to avoid exploitation and improve the circumstances of the local communities to raise awareness of the role of education, healthcare and childcare.

One such example is a cross-sector association called the "Responsible Mica Initiative - towards a responsible Indian mica supply chain".

The Responsible Mica Initiative is a collaboration between the private, public, and non-profit sectors, launched with the aim of achieving a 100% responsible mica supply chain in India over 5 years. It was formed in early 2017. Prior to its formation many of the RMI’s founding members were engaged in efforts to eliminate child labour and poor working conditions, including the provision of schools and medical facilities. In 2016 companies involved in the mica supply chain in a number of industries came together with civil society organisations in India and Terre des Hommes Nederlands to convene the first Mica Summit in Delhi(1).

Terre des Hommes Nederlands is part of the Terre des Hommes International Federation, which was founded in 1960. Their main aim is fighting child exploitation, removing children from exploitative situations to ensure those children can develop in a safe environment(5).

Why is Mica used in cosmetics?

The cosmetics industry has used many chemicals to provide lustre and sparkle to their products. Fish scales were widely used, particularly in nail enamels in the early part of the 20th century. In the early 1960s cosmetic grade bismuth oxychloride was made available. Bismuth oxychloride has a high lustre when wet, but this is lost when it is dried. Whilst it helps in the manufacturing process for lipsticks and eyeshadows, it is not particularly light stable. Due to the popularity of clear packaging bismuth oxychloride has dropped out of favour as a pearl effect pigment in Europe.

To give a good pearlescent effect, a layered substate is preferred. An ideal white pearl effect pigment would be monocrystalline lamella titanium dioxide, as titanium dioxide has a high refractive index, particularly in its anatase form. This unfortunately is not available; the next best option is to deposit anatase titanium dioxide onto a lamella substrate(3).

Natural mica is an ideal substance to act as the substrate. It is transparent, chemically inert, temperature resistant and readily available. Alone, mica has a soft shimmer. It works well as a “filler” in facial products, decorative cosmetics such as foundation and face powder, and skin care products. Fillers are used to enhance skin radiance or provide a matte finish, to disguise fine lines and wrinkles by optical blurring (a process known as soft focus) and to generally even out skin tone.

To produce fillers or pearl effect pigments mica is ground into thin, flexible lamellae and classified into different particle size distributions. Larger particles produce a sparkle in finished products, whereas small particles give more of a sheen. The titanium dioxide in white pearl effect pigments is formed in-situ. Depending on the thickness of the titanium dioxide layer deposited around the mica, either a pure white pearl effect pigment or an interference pearl effect pigment is produced(3).

Mica can also be coated with other metal oxides provided they have a high refractive index, and the metal oxide can be coated onto the mica in a transparent form. Haematite iron oxide has a refractive index of 2.9 and the coating process can be controlled so that it deposits as a transparent crystal(3).

Coating mica with the haematite iron oxide produces bronze, copper, and red pearl effect pigments, depending on the thickness of the coating. By coating the mica with titanium dioxide and then haematite it is possible to manufacture gold pearl effect pigments, the shade of gold achieved is also determined by controlling the thickness of the layers. Varying the layer thickness can also enable the formation of other colours of pearl effect pigments, such as red, red-brown, violet, or even green(3).

Other metal oxides can also be used with titanium dioxide to give blue or green pearl effect pigments. To produce pink and mauve shades carmine is used with titanium dioxide.

By depositing other substances onto the mica, such as barium sulphate or silica a whole range of fillers can be produced to help achieve multiple effects in skin care products.

Metal oxide coated mica products are used in virtually all types of decorative cosmetics, they are particularly useful in lip, eye and nail products(4).

What are the alternatives?

Other effect pigments have been developed in recent years. Importantly pearl effect pigments based on synthetic mica (INCI Synthetic Fluorphlogopite) are now available, but may be at a cost premium compared to natural mica products. There is not yet a match to all products produced on natural mica using synthetic mica, but more are being launched all the time. Synthetic mica has a brighter, whiter, cleaner appearance than natural mica, which can change the effect in the final product(4).

Other substrates are also now available, such as borosilicates, silica and alumina. The borosilicate substrates are particularly transparent, this results in a range of products with exceptional depth of colour and unique colour effects(4).

Products based on silica exhibit a much cleaner mass-tone. This substrate also offers the opportunity to produce colour travel effect pigments, as can using alumina as the substrate(4).

Moving away from natural mica to pearl effect pigments based on other substrates might not however be the best alternative. For many impoverished families, their participation in the mica supply chain is their only source of income(1). To remove this income would almost certainly result in increased poverty and deprivation. Moving to responsibly sourced natural mica should help ensure that the families involved have access to health care and education for their children(1).

What is the industry doing?

Even before the formation of the Responsible Mica Initiative many of the suppliers of natural mica-based ingredients to the cosmetics industry had been working in Jharkhand and Bihar provinces of India. They had signed up to the United Nations Global Compact, issued Human Rights Charters and published details of the requirements they had placed on their supply chain. These included the prohibition of child labour anywhere within the supply chain. The companies were also carrying out audits (both planned and unplanned) of all stages of their supply chain to ensure compliance.

One company had also been funding, with partners in India, schools in Jharkhand province. They also established a health centre to serve 20,000 people in the region.

Some companies had only ever used natural mica mined in North America, therefore child labour in the mines was never an issue.

The formation of the Responsible Mica Initiative (RMI) in 2017 brought together companies who had been working individually on the issue of child labour within the mica supply chain. Initially there were 20 member companies, but by the end of that year the number of members had risen to 39(1). Immediately RMI began to introduce their goals and strategies to Governments, companies, intergovernmental and industry organisations. They prepared responsible workplace standards for mines and mica processing units(1).

What can the consumer do?

The cosmetic and personal care industry is ideally positioned to promote to its consumers the benefits of using products manufactured using sustainably and responsibly resourced ingredients. Members may wish to provide information about their use of responsibly sourced mica-based ingredients, to encourage consumers to consider this important topic and highlight how buying reputable products can prevent child labour in the mica supply chain.

By doing this, members will help consumers understand what is in their products and give them a wider perspective on the use of mica-based products, not just in the cosmetic and personal care industry but in a wider context. CTPA is committed to helping consumers understand what is in the products that they use and to trust that the ingredients used within them are from sustainable sources.

Since then the RMI has engaged partners to launch Community Empowerment programmes in villages in India; rolled out Responsible Workplace Standards to mica processors; presented their programme at many intergovernmental and industry events; started information sharing with key ministries in both Bihar and Jharkhand provinces; held several more RMI General Assemblies; and signed a memorandum of understanding with the Responsible Minerals Initiative amongst other initiatives. At the end of 2019 RMI had 59 members(1).

Resources

- https://india.mongabay.com/2019/10/mica-scavenging-in-jharkhand-destroys-lives-and-environment/

- https://www.refinery29.com/en-us/2019/05/229746/mica-in-makeup-mining-child-labor-india-controversy

- https://thesustainabilityproject.life/blog/2020/09/27/mining-mica/

- https://www.theguardian.com/global-development/2017/may/08/india-to-legalise-mica-mining-bid-tackle-endemic-child-labour-guardian-investigations

- https://satyarthi.org.in/

- https://www.terredeshommes.nl/en

- https://www.greenbiz.com/article/inside-beautycounters-quest-transform-its-mica-supply-chain

- https://www.britannica.com/science/mica

- https://responsible-mica-initiative.com/

- https://mineralseducationcoalition.org/minerals-database/mica/

How can I use Responsibly Sourced Mica?

Several CTPA members are already members of RMI. Companies may wish to consider becoming members of RMI to help ensure that the mica used is responsibly sourced. RMI has three membership levels:

- Active Members – companies that produce or use mica in their business activities or products. This grade of membership also includes organisations such as non-profit industry associations, civil society and NGOs that contribute to RMI objectives and programmes(1).

- Honorary Members – companies or organisations that volunteer their services or expertise to support RMI objectives or programmes(1).

- Associate Members – local communities and organisations which can contribute to defining and developing ethical sourcing practices and otherwise support RMI’s objectives and programmes(1).

Membership fees are applicable for Active Members, these are based on the company’s annual revenues and profit(1).

If CTPA members do not feel that becoming Active Members of RMI is appropriate then CTPA recommends that they review their supply chain for the raw materials they use, which are based on mica, to ensure that they are supplied by a company with robust procedures in place. This may be an RMI member company.

By promoting how they use sustainable ingredients, members can help educate consumers and raise the overall awareness of the issues around mica, showing that moving away from the use of natural mica may not be the answer and could result in more poverty.

What is the industry doing?

Even before the formation of the Responsible Mica Initiative many of the suppliers of natural mica-based ingredients to the cosmetics industry had been working in Jharkhand and Bihar provinces of India. They had signed up to the United Nations Global Compact, issued Human Rights Charters and published details of the requirements they had placed on their supply chain. These included the prohibition of child labour anywhere within the supply chain. The companies were also carrying out audits (both planned and unplanned) of all stages of their supply chain to ensure compliance.

One company had also been funding, with partners in India, schools in Jharkhand province. They also established a health centre to serve 20,000 people in the region.

Some companies had only ever used natural mica mined in North America, therefore child labour in the mines was never an issue.

The formation of the Responsible Mica Initiative (RMI) in 2017 brought together companies who had been working individually on the issue of child labour within the mica supply chain. Initially there were 20 member companies, but by the end of that year the number of members had risen to 39(1). Immediately RMI began to introduce their goals and strategies to Governments, companies, intergovernmental and industry organisations. They prepared responsible workplace standards for mines and mica processing units(1).

Since then the RMI has engaged partners to launch Community Empowerment programmes in villages in India; rolled out Responsible Workplace Standards to mica processors; presented their programme at many intergovernmental and industry events; started information sharing with key ministries in both Bihar and Jharkhand provinces; held several more RMI General Assemblies; and signed a memorandum of understanding with the Responsible Minerals Initiative amongst other initiatives. At the end of 2019 RMI had 59 members(1).

References

(1) Responsible Mica Initiative

(2) SOMO Report Global Mica Mining and The Impacts on Children’s Rights (March 2018)

(3) Pearl Lustre Pigments – Physical Properties, Properties, Applications by Roman Maisch and Manfred Weigand (translated by J H Steele). Published in collaboration with E Merck Germany (now Merck KGaA).

(4) Coloring the Cosmetic World: Using Pigments in Decorative Cosmetic Formulations by Edwin B Faulkner. Published by Allured Books ISBN 9781932633979