This page covers the below sections:

This page covers the below sections:

- How do cosmetic ingredients enter the environment

- Predicting the environmental concentration

- Biodegradability of Ingredients - Principles and Examples

- Assessing biodegradability

- Biodegradability of plastics

- Photodegredation of plastics

- Environmental Claims

- Resources

- References

See the Contents for all available Sustainability Hub pages.

As the public becomes more and more concerned about the effect that they, and the products they use, have on the environment, the personal care industry needs to look closely at the ingredients used, to ensure that they have as little environmental impact as possible. In 2015 the EU Commission conducted a consumer market study on environmental claims for non-food products, which included cosmetic products. This study showed that consumers found it difficult to understand which products are truly environmentally friendly(1).

In a study conducted by Cosmetics Europe it was found that the raw materials in a shampoo contributed up to 20% of the shampoo’s total life cycle environmental impact(2). By looking carefully at the ingredients used in the product it should be possible to reduce this impact.

How do cosmetic ingredients enter the environment?

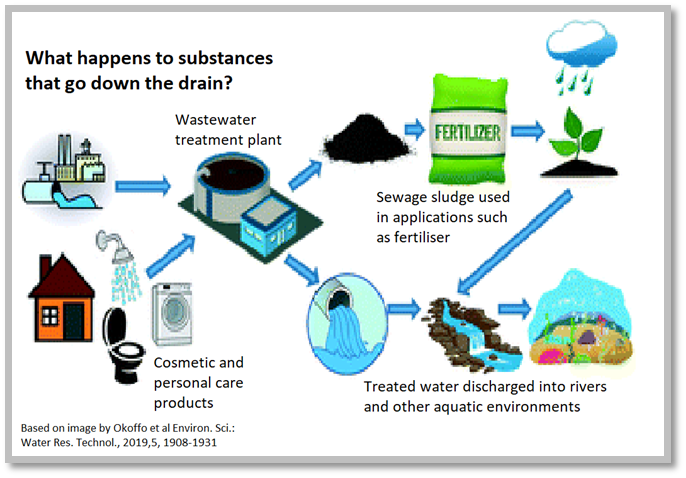

Many cosmetic products are disposed down the drain after use. Consideration has to be made as to whether the water is treated by wastewater treatments plants or goes directly into the aquatic environment.

Many cosmetic products are disposed down the drain after use. Consideration has to be made as to whether the water is treated by wastewater treatments plants or goes directly into the aquatic environment.

Evaporation and release to air must also be considered for certain volatile products.

Predicting the environmental concentration

Different pieces of information are required to calculate the concentration of a cosmetic ingredient in the environment. These must consider the amount going down the drain and what happens to the ingredient in the environment; for example, whether it biodegrades, what happens to it in water treatment plants and which locations it travels to. The following need to be reviewed:

- Volume information – how much product is used and released by consumers?

- The physiochemical properties of the ingredient - how it deposits between soil, sediment, water, and the atmosphere.

- An understanding of what happens to the ingredient in the environment – data from internationally standardised tests demonstrating that it biodegrades under appropriate conditions.

- Specially developed computer models are available which take into account a large number of variables to estimate the environmental concentration of chemicals.

Predicted environmental concentrations are usually used rather than actual measurements of how much of the chemical is in the environment. A measurement only provides one snapshot in time whereas a prediction based on a model is cheaper and covers different scenarios, locations, and conditions.

For further information on assessing the environmental fate of cosmetic ingredients, please see the Environmental Fate page.

Biodegradability of ingredients – Principles and Examples

Chemicals can degrade in a number of ways. By reacting with water, hydrolysis, by reacting with light, photodegradation, or by reacting with biological speciessuch as enzymes, biodegradation.

Biodegradation of organic compounds is the most prevalent degradation mechanism in both aquatic and terrestrial environments(3)(4).

How chemicals biodegrade can depend on their chemical structure, for example substances with a linear alkyl chain biodegrade more easily than those with a branched alkyl chain(3)(4).

The American Chemical Society sets out the 12 Principals of Green Chemistry(4). Green Chemistry Principal 10 is “Design for Degradation”, which is defined as:

- “Chemical products should be designed so that at the end of their function they break down into innocuous degradation products and do not persist in the environment”

Biodegradation, hydrolysis and photodegradation can be designed into chemical products. For example, many persistent chemicals are extensively chlorinated. Halogens are electron withdrawing and therefore inhibit the enzyme systems of microbes because aerobic microbial degradation favours electron rich structures(4).

Structures that can aid biodegradation are esters, oxygen (except when present as an ether) and unsubstituted linear alkyl chains. Those that hinder are halogens, chain branching, nitrogen, polycyclic residues, heterocyclic residues and aliphatic ether bonds (except in ethoxylates)(4).

Many consumers assume that because an ingredient or product claims to be natural it will biodegrade quite readily, unfortunately this is not always the case.

Squalene, now derived from olives or amaranth oil rather than sharks’ livers, is a popular ingredient in natural skin care products. As a triterpene hydrocarbon it contains six double bonds, meaning that enzymic biodegradation is difficult. No enzymes or genes involved in the microbial degradation of Squalene have yet to be identified(5). Squalane on the other hand, made by hydrogenation of Squalene, is fully saturated and therefore biodegrades readily. Using Squalane in a formulation rather than Squalene would therefore result in a more biodegradable product.

Assessing biodegradability

In 1992 the EU Ecolabel scheme was established. A wide range of products are now within scope of Ecolabel. One of the groups covered is Rinse-off cosmetic products(6). The Commission Decision establishing the ecological criteria for the award of EU Ecolabel for rinse-off cosmetic products, was notified in December 2014(7).

The Commission Decision gives details of assessment and verification requirements and specifically mentions that the Appendix refers to the “Detergent Ingredient Database” (DID) list. This contains the most widely used ingredients in detergents and rinse-off cosmetic products and is used to calculate the Critical Dilution Volume (CDV) and the assessment of the biodegradability of the ingredients in the formulation(7). Even for companies that do not wish to apply for the Ecolabel system the DID list contains useful data to help look at the biodegradability of the ingredients that they use.

Copies of the DID list are available from the Ecolabel website(5)(8).

For ingredients not on the latest DID list, Part B of the Detergents Ingredient Database (2016) gives information on how to calculate the CDV and the data that is needed for this calculation(9).

The DID list gives information on various types of surfactants but also other chemicals, such as preservatives, thickening agents and many other ingredients commonly used in cosmetic rinse-off products(5). Perfumes and dyes are exceptions, generic figures for these are given in the list, although it is, of course, preferable to use actual data if it is available.

The determination of biodegradability can depend on the test protocol used. It is recommended that the test methods published by OECD are used. It is suggested that for aerobic biodegradability the methods used are OECD 301 A-F or 310 for readily biodegradable or 302 A-C for inherently biodegradable. For anaerobic biodegradability OECD test 311 is one of those recommended(9).

OECD test methods can be obtained via the OECD website(10).

The environmental fate of non-rinse-off products is quite different, although eventually much of the product will be washed off the skin when the consumer next bathes, showers or washes their hands or face. A study conducted for Cosmetics Europe showed that 75% of the make-up users surveyed, removed their make-up with cotton or wipes, 95% of which were disposed of in the waste bin(11). From this we can assume that much of the make-up produced eventually ends up in landfill or incineration, depending on the final fate of the general waste in a customer’s country.

This means that as an industry we also need to consider the breakdown products of the ingredients to ensure that, when they decompose in a landfill site, they do not add toxins to the leachate or contribute to the production of greenhouse gasses. In testing for this it must be remembered that much of the degradation in a landfill site is anaerobic. When landfill sites are full, they are covered with a layer of clay or vegetation, which forms a barrier, keeping odours in and rainwater out. As a result, oxygen is removed and the organic material present in the landfill can only degrade anaerobically. The appropriate OECD test methods, mentioned above, therefore should be used to establish the biodegradability of the chemicals.

Biodegradability of plastics

It is not just the products themselves that need to be considered. All of our products are packaged in some form. Much of this packaging is plastic, and not all plastic is biodegradable. As with the chemicals used in cosmetic products, suitable tests for biodegradability of plastics must be carried out to avoid unintended consequences and encourage the development of high-quality biodegradable materials(12).

The vast majority of plastics are produced from non-renewable, petrochemical sources. Bioplastics are derived from biological sources, often referred to as plant-based(12). Biodegradability of plastics can be described as the breakdown of plastic monomers or polymers due to biological processes. Biodegradable materials can be converted to biomass, carbon dioxide and water. In anaerobic conditions, such as landfill sites, methane can also be produced(12). How biodegradable a material really is looks at the rate of degradation in the environment, which depends on the chemical composition and where the material ends up. In controlled environments processes are managed, meaning the timescales can be standardised, but natural environments are far more complex(12).

Testing the biodegradation properties of a material therefore involves attempting to control these factors to better understand the breakdown processes, timescales and products formed when the material undergoes biodegradation(12).

The EU Directive on Packaging and Packaging Waste (94/62/EC), and its subsequent amendments, led to the publication of EU harmonised standards for compostable and biodegradable packaging – EN 13432:2000 - “Packaging: requirements for packaging recoverable through composting and biodegradation” in 2000. This was adopted by national standards bodies throughout the EU, in the UK it was adopted by the British Standards Institution and published as BE EN 13432:2000. Its scope is specifically compostability and anaerobic digestability of packaging(13).

Key tests and Pass/Fail criteria for the Compostable claim under BS EN 13432:2000 are:

- Disintegration – the packaging sample is mixed with organic waste and maintained under test scale composting conditions for 12 weeks after which time no more than 10 % of material fragments are allowed be larger than 2 mm.

- Biodegradability - a measure of the actual metabolic, microbial conversion, under composting conditions, of the packaging sample into water, carbon dioxide and new cell biomass. Within a maximum of 6 months, biodegradation of the test sample must generate an amount of carbon dioxide that is at least 90 % as much as the carbon dioxide given off from the control / reference material.

- Absence of any negative effect on the composting process.

- Low levels of heavy metals (Potentially Toxic Elements) and no adverse effect of the quality of compost produced. Upper limits, in mg/kg of dry sample, are: zinc 150, copper 50, nickel 25, cadmium 0.5, lead 50, mercury 0.5, chromium 50, molybdenum 1, selenium 0.75, arsenic 5 and fluoride 100.

- The composted packaging material must not have adverse effect on the bulk density, pH, salinity (electrical conductivity), volatile solids, total nitrogen, total phosphorus, total magnesium, total potassium and ammonium nitrogen characteristics of the compost.

Each of these tests is undertaken according to internationally agreed methods of test, as specified in BS EN 13432. Independent laboratory test results are then compared with the strict pass/fail limits set in the standard. Only if a material passes every ‘compostable’ test requirement is it proven to be ‘compostable’(13).

Other relevant standards, also available from BSI Group include:

- BS EN 14646:2003 – Packaging: Evaluation of the ultimate aerobic biodegradability and disintegration of packaging materials under controlled composting conditions. Method by analysis of released carbon dioxide

- BS EN 14995:2006 Plastics: Evaluation of compostability. Test scheme specifications.

- BS ISO 13975:2019 Plastics: Determination of the ultimate anaerobic biodegradation of plastic materials in controlled slurry digestion systems. Method by measurement of biogas production.

- BS EN ISO 14853:2017 Plastics. Determination of the ultimate anaerobic biodegradation of plastic materials in an aqueous system. Method by measurement of biogas production.

- BS EN ISO 14985:2017 Plastics: Determination of the ultimate anaerobic biodegradation under high-solids anaerobic-digestion systems. Method by measurement of biogas production.

Independent certification bodies offering product assessment and certification services for BS EN 13432:2000 are available. If a product passes the required test a unique packaging product certification number and certificate is awarded, and the product may then carry the scheme’s logo ”compostable”. In the UK, the Association for Organics Recycling operates a certification scheme in partnership with the German certification body Din Certco, aligned to the requirements of BS EN 13432:2000(13).

There are currently no specific international or national standards for home compostable packaging and plastics. However, work is ongoing to develop a system for the UK like that in Belgium, which can lead to a claim of “OK Compost Home”(13).

Photodegradation of plastics

Photodegradation is the process of decomposition of a material by the action of light. It is considered one of the primary sources of damage exerted on polymeric substances at ambient temperatures. Most synthetic polymers are susceptible to degradation by both UV and visible light(14).

Photodegradable plastics are designed to become weak and brittle when exposed to sunlight for prolonged periods. When manufactured light-sensitive chemical additives or copolymers are included, these weaken the bond of the polymer in the presence of UV radiation. These plastics degrade in a two-stage process. UV light initially breaks some bonds resulting in lower molecular weight compounds that further degrade from physical stress. However, this form of degradation can result in the formation of microplastics(14).

The mechanism of photodegradation of polyethylene (PE) is well understood. Polypropylene (PP) is resistant to photo-oxidation but is sensitive to heat, light and radiation. Sunlight at the surface of the earth is sufficient to start degradation and cause discolouration and chalking as well as making it brittle. UV light causes serious degradation, weakening it. Photodegradation of Polyethylene Terephthalate (PET) occurs after exposure to near-ultraviolet. When exposed to UV light PET degrades quite rapidly leading to deterioration in physical and mechanical properties, it also develops a yellow colour(14).

Environmental Claims

Environmental claims for cosmetic products and their packaging must follow the same requirements as all other cosmetic claims. Claims should not be too broad or vague. Guidance documents and recommendations from the EU Commission, the Advertising Standards Authority (ASA) and the UK Department for the Environment, Food and Rural Affairs (Defra) conclude that claims should meet the following requirements(1).

- Reflect a verifiable environmental benefit over the full product lifecycle, if this is not available then companies should be transparent about which area of the supply chain the environmental benefit is related to.

- Consumers must not be misled and should instead be educated on the topic, to be allowed to make an informed decision. Relevant information to the consumer should not be omitted.

- Environmental claims should be correct and based on sound science. Substantiation should be relevant to the real lifecycle of the product, not in controlled laboratory conditions. Specific measurements or standards are available for companies; for example, International Standards Organisation (ISO), European Committee for Standardisation (CEN) and British Standards Institute (BSI).

- Companies should not make exaggerated claims that are difficult to prove, such as ‘environmentally friendly’, ‘fully biodegradable’, or similar.

- The claimed environmental benefit should not cause or contribute to another environmental problem.

The European Green Deal was launched by the EU Commission in December 2019. This includes specific reference to environmental and green claims, with the aim of reducing “greenwashing”. It quotes that:

- “Companies making ‘green claims’ should substantiate these against a standard methodology to assess their impact on the environment. The Commission will step up its regulatory and non‐regulatory efforts to tackle false green claims. Digitalisation can also help improve the availability of information on the characteristics of products sold in the EU”.

In the UK there are no specific guidelines or regulations for green claims on cosmetic products. It is recommended that reference is made to the Committee of Advertising Practice (CAP) guide on the ASA position on environmental claims(14).

Please refer to the CTPA Guide on Environmental and Green Claims for additional information and guidance.

Resources

This paper outlines a methodology to help companies maximise their use of biodegradable ingredients.

The European Chemicals Agency (ECHA) has produced guidance on ready biodegradability tests, which is available here.

An overview of general biodegradation potential for different classes of cosmetic ingredients may be found here.

A comprehensive review, focussing on surfactants, covering environmental properties including biodegradability is available here.

References

- CTPA Guide to Environmental and Green Claims

- Cosmetics Europe Environmental Sustainability Report 2019

- The Green Chemistry Initiative Blog - Principle #10

- ACS - 12 Principles of Green Chemistry

- Biodegradation of Natural Rubber and Related Compounds: Recent Insights into a Hardly Understood Catabolic Capability of Microorganisms Karsten Rose, Alexander Steinbüchel Applied and Environmental Microbiology Jun 2005, 71 (6) 2803-2812; DOI: 10.1128/AEM.71.6.2803-2812.2005

- European Commission - Ecolabel

- COMMISSION DECISION - of 9 December 2014 - establishing the ecological criteria for the award of the EU Ecolabel for rinse-off cosmetic products

- European Commission - Detergents Ingredients Database 2016

- European Commission - Detergents Ingredients Database PART B

- OECD - Guidelines for the Testing of Chemicals, Section 3

- Cosmetics Europe - ECHA workshop 30-31st May 2018 Intentionally added microplastics to products Break-out session: Cosmetics

- A review of standards for biodegradable plastics; by the Industrial Biotechnology Innovation Centre 2019.

- British Plastics Federation - Packaging Waste Directive and Compostable Packaging

- Fotopoulou, Kalliopi & Karapanagioti, Hrissi. (2017). Degradation of Various Plastics in the Environment. 10.1007/698_2017_11.