This page covers the below sections:

This page covers the below sections:

- What is Green Chemistry?

- The Twelve Principles

- Benefits of Green Chemistry

- Life Cycle Thinking

- UNIDO Global Green Chemistry Project

- EU Commission's Chemical Strategy for Sustainability

- References

See the Contents for all available Sustainability Hub pages.

What is Green Chemistry?

Green chemistry is a set of principles and guidelines that encourage chemists to design more efficient chemical processes, producing more of the chemical they want, with less unwanted by-products. Most cosmetic ingredients are made using chemical processes to transform chemicals, including natural ingredients, into something more useful and, of course, safe when applied to the human body. The principles of green chemistry aim to ensure that chemists use less energy, less water and solvents, and fewer process steps (a smaller series of reactions).

Green chemistry does not mean "no chemistry". Modern chemistry is essential for our modern lifestyle and the products we take for granted, from cars to consumer electronics and from clothing to cosmetics. However, green chemistry uses modern and innovative techniques so that chemistry is more efficient and less damaging to the environment.

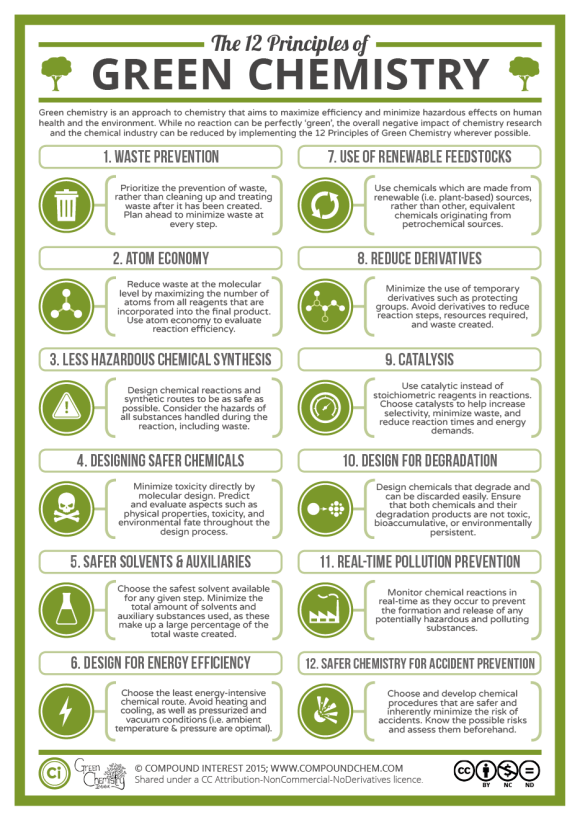

The Twelve Principles

The commonly accepted Twelve Principles of Green Chemistry(1) are:

- Prevent waste: Design chemical syntheses to prevent waste, leaving no waste to treat or clean up.

- Design safer chemicals and products: Design chemical products to be fully effective yet have little or no toxicity.

- Design less hazardous chemical syntheses: Design syntheses to use and generate substances with little or no toxicity to humans and the environment.

- Use renewable feedstocks: Use raw materials and feedstocks that are renewable rather than depleting. Renewable feedstocks are often made from agricultural products or are the wastes of other processes; depleting feedstocks are made from fossil fuels (petroleum, natural gas, or coal) or are mined.

- Use catalysts, not stoichiometric reagents: Minimize waste by using catalytic reactions. Catalysts are used in small amounts and can carry out a single reaction many times. They are preferable to stoichiometric reagents, which are used in excess and work only once.

- Avoid chemical derivatives: Avoid using blocking or protecting groups or any temporary modifications if possible. Derivatives use additional reagents and generate waste.

- Maximize atom economy: Design syntheses so that the final product contains the maximum proportion of the starting materials. There should be few, if any, wasted atoms.

- Use safer solvents and reaction conditions: Avoid using solvents, separation agents, or other auxiliary chemicals. If these chemicals are necessary, use innocuous chemicals.

- Increase energy efficiency: Run chemical reactions at ambient temperature and pressure whenever possible.

- Design chemicals and products to degrade after use: Design chemical products to break down to innocuous substances after use so that they do not accumulate in the environment.

- Analyse in real time to prevent pollution: Include in-process real-time monitoring and control during syntheses to minimize or eliminate the formation of by-products.

- Minimize the potential for accidents: Design chemicals and their forms (solid, liquid, or gas) to minimize the potential for chemical accidents including explosions, fires, and releases to the environment.

© Compound Interest 2015 www.compoundchem.com

Green Chemistry is sometimes referred to as Sustainable Chemistry. The OECD defines this as:-

"Sustainable chemistry is a scientific concept that seeks to improve the efficiency with which natural resources are used to meet human needs for chemical products and services. Sustainable chemistry encompasses the design, manufacture and use of efficient, effective, safe and more environmentally benign chemical products and processes.”(2)

The OECD goes on to say:-

Sustainable chemistry is also a process that stimulates innovation across all sectors to design and discover new chemicals, production processes, and product stewardship practices that will provide increased performance and increased value while meeting the goals of protecting and enhancing human health and the environment.(2)

OECD points out that the environmental and societal benefits of sustainable chemistry include:

- Avoiding the use of persistent, bioaccumulative, toxic, and otherwise hazardous materials.

- Using renewable resources and decreasing consumption of non-renewable resources.

- Minimising negative environmental impacts of chemical processing and manufacturing.

- Providing technologies that are economically competitive for and advantageous to industry.(2)

Benefits of Green Chemistry

The US Environmental Protection Agency (US EPA) lists the benefits of green chemistry for human health, the environment and economy and business(3). These include:-

Human health:

- Cleaner air

- Cleaner water

- Increased safety for workers in the chemical industry

- Safer consumer products of all types

- Safer food

- Less exposure to toxic chemicals posing a risk to health

Environment:

- Many chemicals end up in the environment by intentional release during use (e.g., pesticides), by unintended releases (including emissions during manufacturing), or by disposal. Green chemicals either degrade to innocuous products or are recovered for further use.

- Plants and animals suffer less harm as they are less exposed to toxic chemicals in the environment.

- Lower potential for global warming, ozone depletion, and smog formation.

- Less chemical disruption of ecosystems.

- Less use of landfills, especially hazardous waste landfills.

Economy and business:

- Higher yields for chemical reactions, consuming smaller amounts of feedstock to obtain the same amount of product.

- Fewer synthetic steps, often allowing faster manufacturing of products, increasing plant capacity, and saving energy and water.

- Reduced waste, eliminating costly remediation, hazardous waste disposal, and end-of-the-pipe treatments.

- Allow replacement of a purchased feedstock by a waste product.

- Better performance so that less product is needed to achieve the same function.

- Reduced use of petroleum products, slowing their depletion and avoiding hazards from certain chemicals and price fluctuations.

- Reduced manufacturing plant size or footprint through increased throughput.

- Improved competitiveness of chemical manufacturers and their customers(4)

US EPA has run the annual Green Chemistry Challenge Awards since 1996. These awards promote the environmental and economic benefits of developing and using novel green chemistry. The awards recognise chemical technologies that incorporate the principles of green chemistry into chemical design, manufacture and use(3).

Life Cycle Thinking

In the preamble to their annual conference on green chemistry and engineering, the American Chemical Society stress that life cycle thinking is an important principal in successfully implementing green chemistry. This approach allows chemists and chemical engineers to think systematically about how the choices they make at one stage of the chemical life cycle can influence the fate of a chemical and the ultimate impacts on society and the environment(4).

When using life cycle thinking chemists should consider:-

- Where do the elements used in this reaction come from? Can the synthetic routes and processes be successfully redesigned in order to eliminate the use of elements facing limits in supply?

- How will the choices scientists and engineers make impact different stages of a chemical’s life cycle?

- How can we use waste or by-products as a resource to produce valuable chemicals?

- How can we make more sustainable chemicals and materials that enable a circular economy?

- How can we design products for recycling, reuse or remanufacture?

UNIDO Global Green Chemistry Project

The United Nations Industrial Development Organization (UNIDO) and partners launched a global green chemistry project to increase global awareness and deploy green chemistry approaches and technologies(4). The UNIDO Green Chemistry multi-stakeholder initiative brings together a broad network of partners, including the Centre for Green Chemistry and Green Engineering at Yale University, the German Federal Environmental Foundation, Braskem, the largest thermoplastic resins producer in the Americas, as well as several National Cleaner Production Centres (NCPCs) from Latin America, Africa, Asia and Eastern Europe. The three-year project is funded by the Global Environment Facility (GEF)(5).

EU Commission’s Chemical Strategy for Sustainability

The European Commission has adopted the EU Chemical Strategy for Sustainability as part of the European Green Deal. One of the main aims of this strategy is to boost the investment and innovative capacity for production and use of chemicals that are safe and sustainable by design throughout their life cycle(6). Part of the strategy for “safe and sustainable-by-design” is the commitment that the EU Commission will:-

- Develop EU safe and sustainable-by-design criteria for chemicals.

- Establish an EU-wide safe and sustainable-by-design support network to promote cooperation and sharing of information across sectors and the value chain and provide technical expertise on alternatives.

- Ensure the development, commercialisation, deployment and uptake of safe and sustainable-by-design substances, materials and products through financial support in particular to SMEs – under Horizon Europe, cohesion policy, the LIFE programme, other relevant EU funding and investment instruments and public-private partnerships.

- Map and address safe and sustainable-by-design skills mismatches and competence gaps and ensure adequate skills at all levels -including in vocational and tertiary education, research, industry and among regulators.

- Establish, in close cooperation with stakeholders, Key Performance Indicators to measure the industrial transition towards the production of safe and sustainable chemicals.

- Ensure that the legislation on industrial emissions promotes the use of safer chemicals by industry in the EU by requiring on-site risk assessments and by restricting the use of substances of very high concern(7).

Green Chemistry and the Cosmetics Industry

The UK’s Government Chemist, part of the Department for Business, Energy and Industrial Strategy, used their Christmas Lecture programme to present a paper on Sustainable Chemistry, given by Professor Tom Welton, of Imperial College London and President of the RSC. Professor Welton looked in some detail at the use of sustainable chemistry in the development of biodegradable chemicals and in particular biodegradable sustainable plastics(8).

The cosmetics industry is ideally positioned to benefit from the use of green chemistry in its raw materials and packaging. As an industry it has been moving away from petrochemical derivatives for a number of years. Much of the chemistry the industry uses from petrochemical sources can also be obtained from plant sources, such as palm oil or coconut oil, thereby meeting principle four of The Green Chemistry Principles.

By looking at the ingredients used it is possible to design products and packaging with greater biodegradability or compostability (Green Chemistry Principle 10). For example, using fully saturated rather than unsaturated carbon chain structures, such as squalane rather than squalene, allows better biodegradability. Some chemical structures can also aid biodegradation, esters, oxygen (except when present as an ether) and unsubstituted linear alkyl chains. However, some structures can hinder biodegradation, such as halogens, chain branching, nitrogen, polycyclic residues, heterocyclic residues and aliphatic ether bonds (except in ethoxylates)(9). For more information on biodegradability and compostability please see the bio-sourcing, biodegradability and composability page.

More information on green chemistry is available at University of York Green Chemistry Centre of Excellence and The American Chemical Society.

References

- Originally published by Paul Anastas and John Warner in Green Chemistry: Theory and Practice. (Oxford University Press: New York, 1998).

- OECD - Sustainable Chemistry

- United States Environmental Protection Agency - Green Chemistry -

- ACS Green Chemistry Institute

- United Nations Industrial Development Organisation (UNIDO)

- European Commission - Chemicals Strategy

- European Commission - Chemicals Strategy for Sustainability Towards a Toxic-Free Environment

- UK Government - Sustainable Chemistry

- ACS - 12 Principles of Green Chemistry